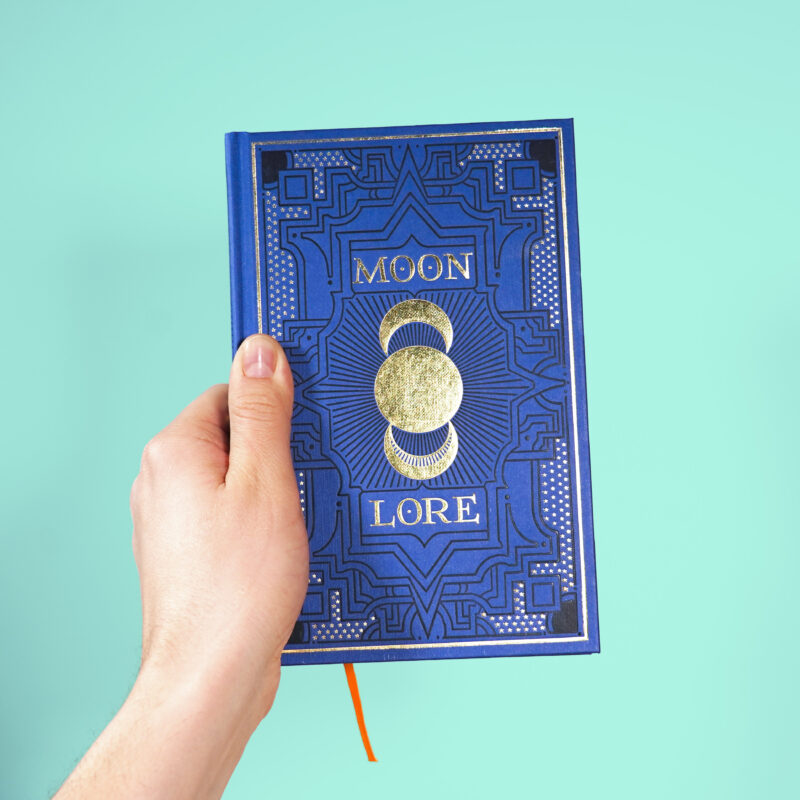

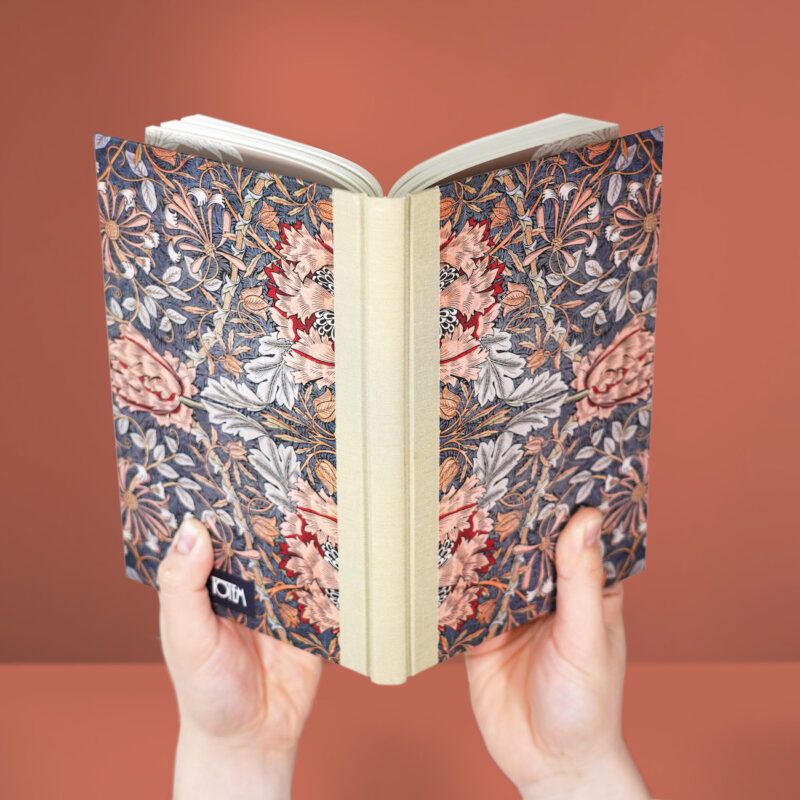

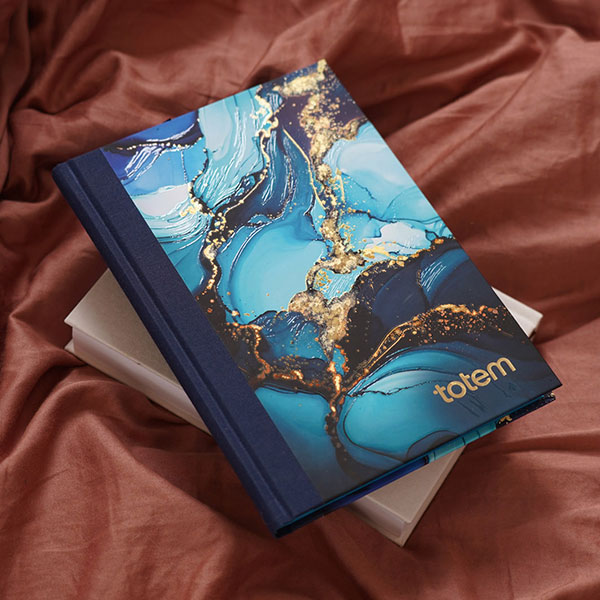

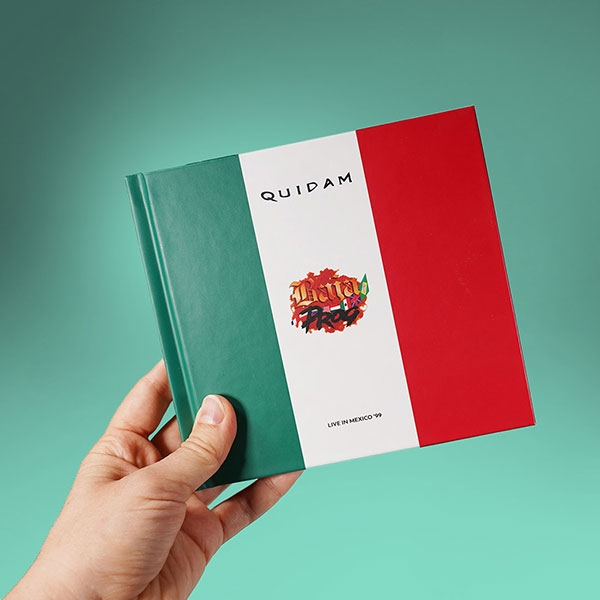

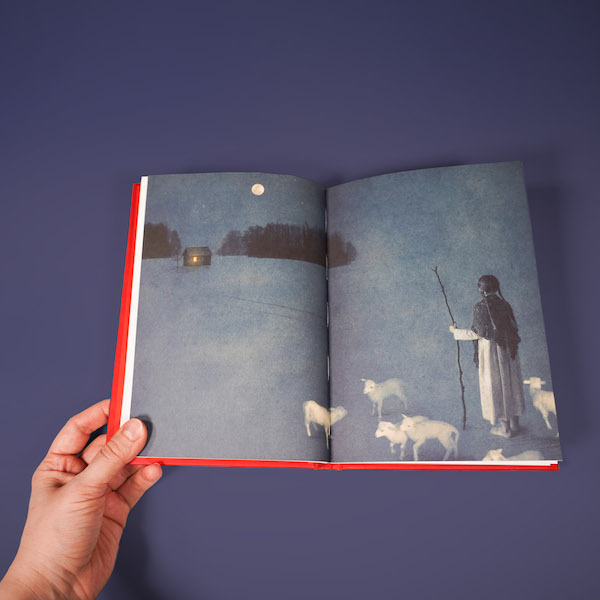

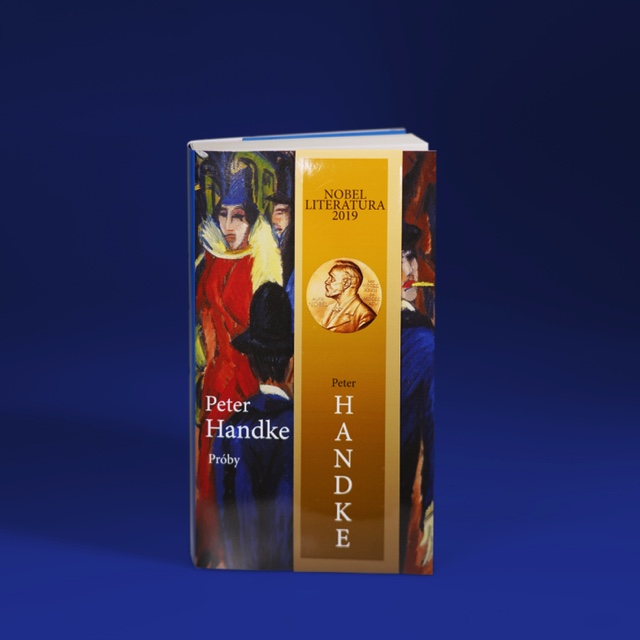

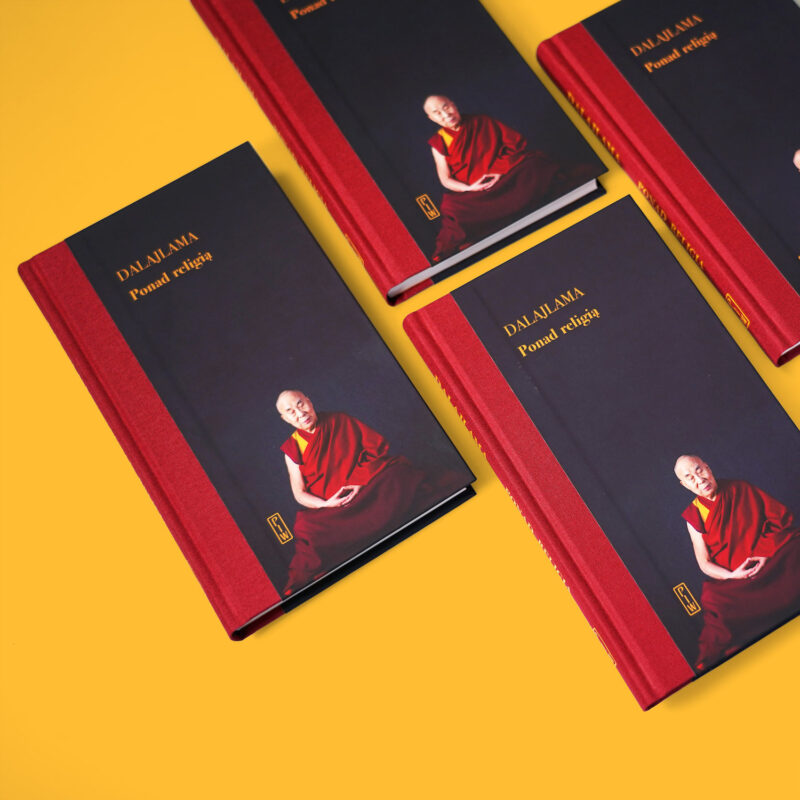

See what your book could look like

I loved books... The feel of them and the smell of them. A bookshop was like an Aladdin’s cave for me. Entire worlds and lives can be found just behind that glossy cover. All you had to do was look.

Want to have your book printed?

Are you an author and a publisher at the same time, but you don’t know how to get started? Check out what we can offer.

What makes us special?

-

Volumes made to measure

- from a few copies to a few thousands

-

Digital book printing – intended for publishing companies and self-publishers

We aim our offer both at experienced professional publishers and individuals who have just set off on their journey into publishing.

-

State-of-the-art technology

-

Care about nature

We strive to make sure that our production processes have as little environmental impact as possible. We use green energy and eco-friendly materials, and we minimise the use of films, favouring energy-efficient printing and bookbinding systems.

-

Assistance and support at every stage of the process

printing, binding and enhancing

-

Highest quality

verified by our client’s opinions and five awards for the Best Digital Printing House in the books and magazines sector.

Let’s talk

We’re happy to advise, answer your questions and provide a quote. Contact us!

You can also write to us: kontakt@totem.com.pl