Enhancement

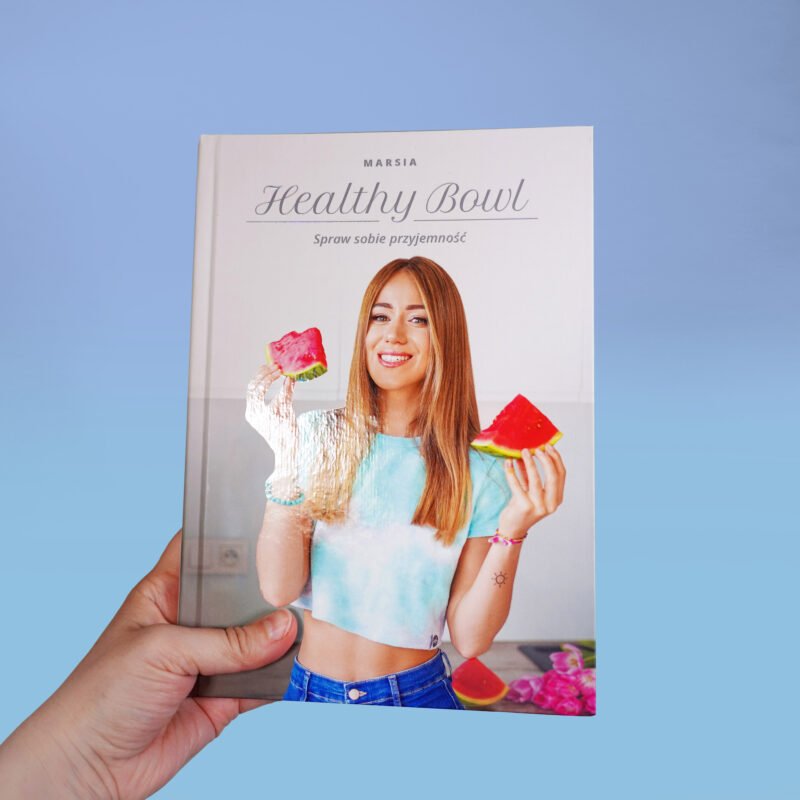

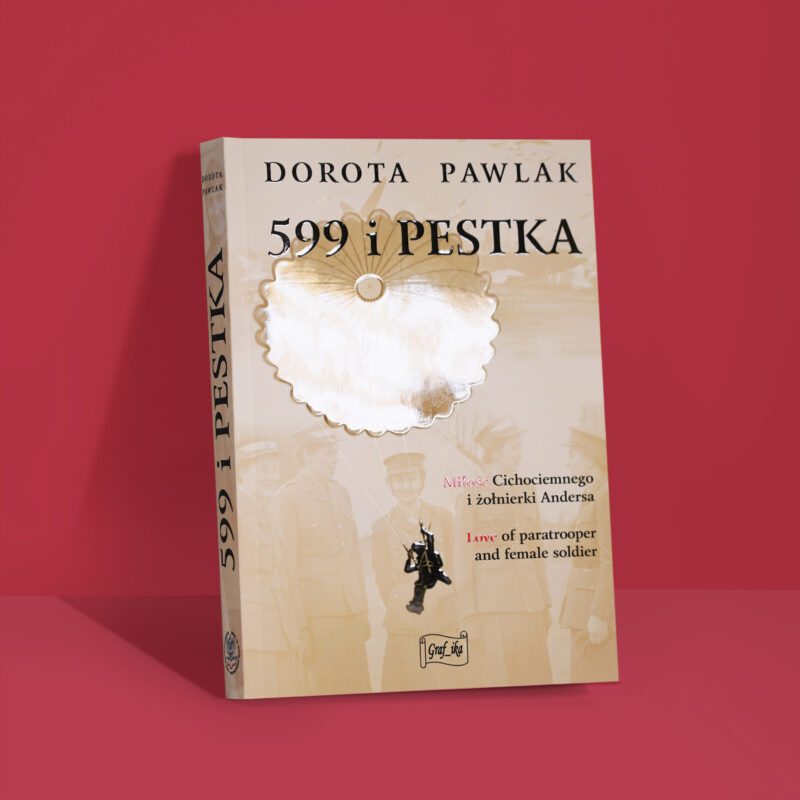

The books we print and bind are made with passion and love. We aim to make them as beautiful as possible. We give particular attention to covers and the ways they can be decorated, because we know that the first impression – what the cover looks like, how it is designed and what emotions it evokes in potential buyers – largely determines its success on the market. We offer many ways to make your cover more attractive, whether it is made of paper, cloth, eco-leather, cork or any other sophisticated material. We provide enhancement for the block edges of your book.

Check out what we have got for you.

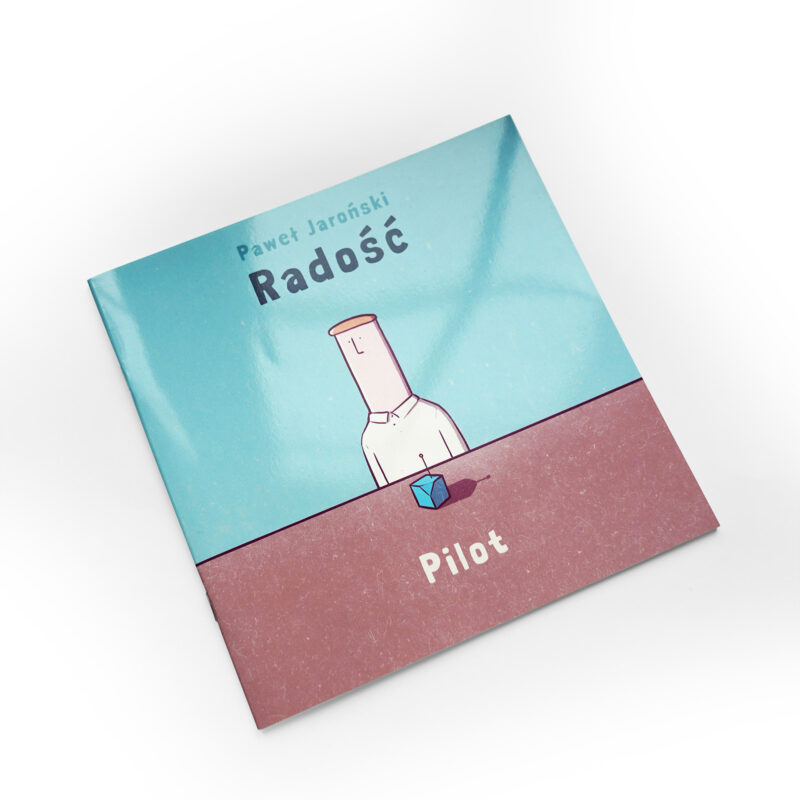

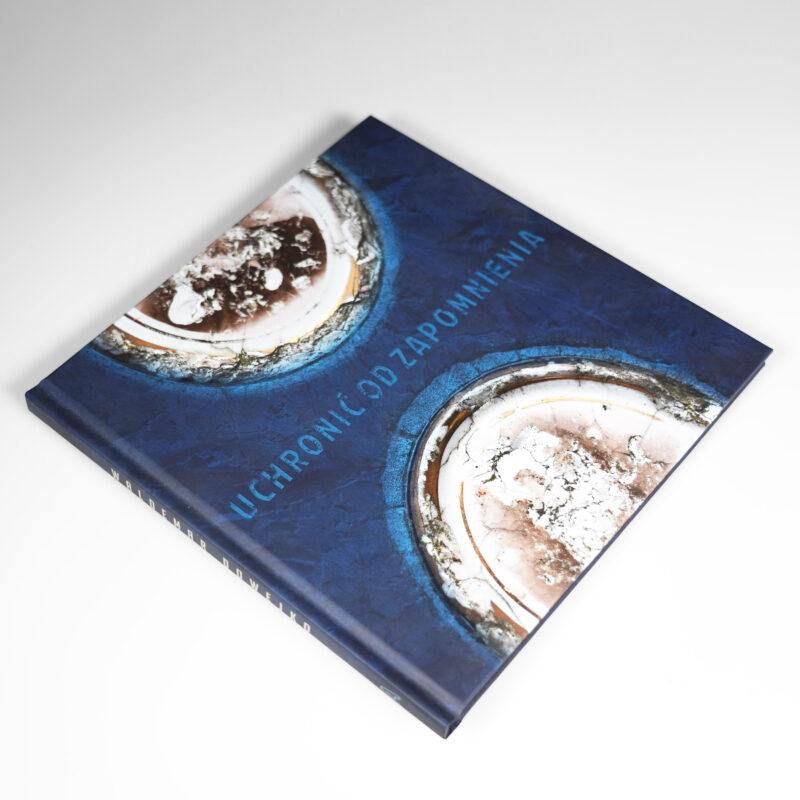

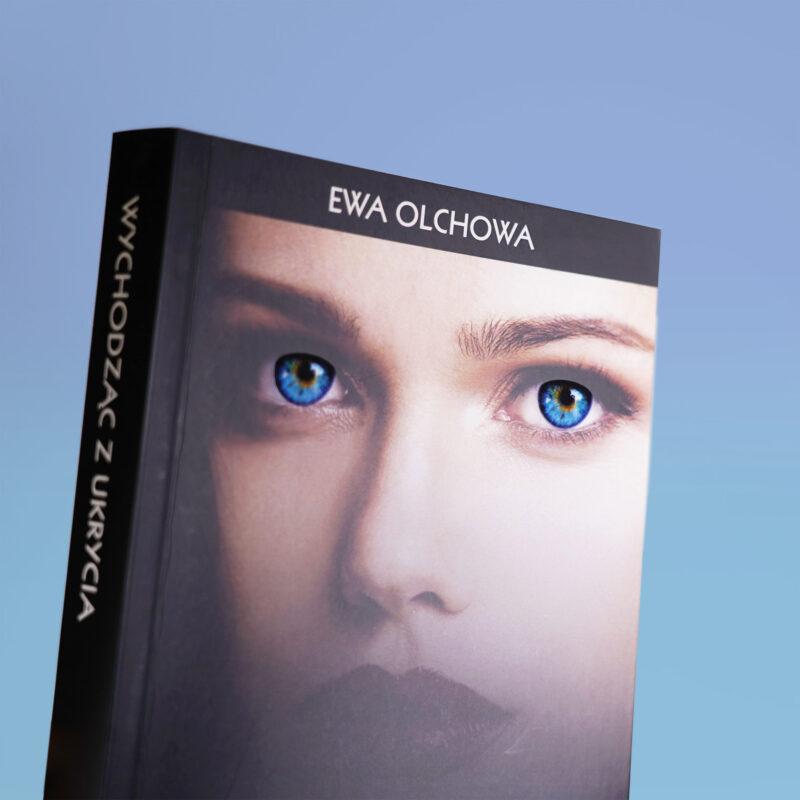

Lamination

Lamination consists in coating the entire surface of the cover with a thin layer of film. It is the most popular form of enhancement. Its main purpose is to protect the cover from scratching and other mechanical damage, as well as from moisture and dirt. In addition, lamination affects the appearance of the cover – applying a film enhances the colours of the print. It also improves the sensory perception of the publication by making the covers pleasant to the touch.

Glossy

spectacular, brings the colours to life

Matte

perfect for spot varnishing

Soft touch

velvety and incredibly nice to the touch

Anti-scratch matte

particularly recommended for dark covers

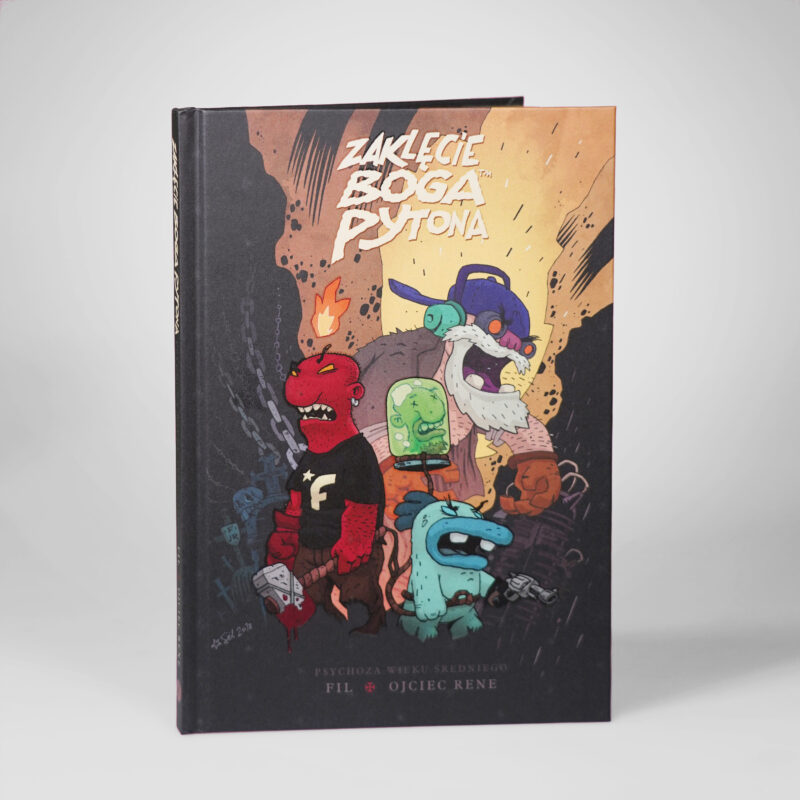

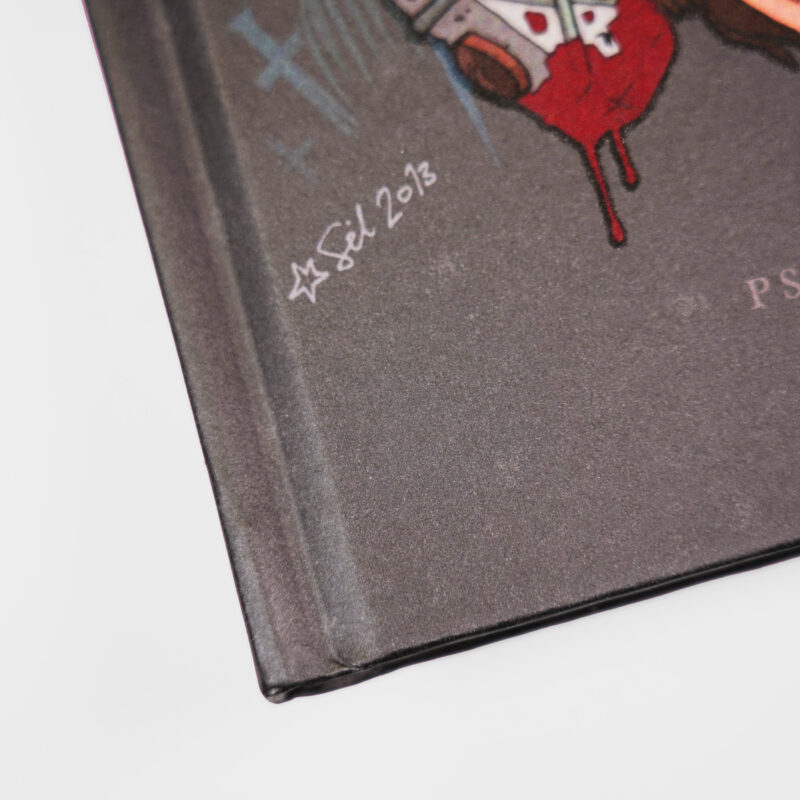

Sandy (gritty)

slightly coarse, creates the illusion of sprinkled sand

Textured (linen)

gives the impression of a linen cover

See also

Varnishes

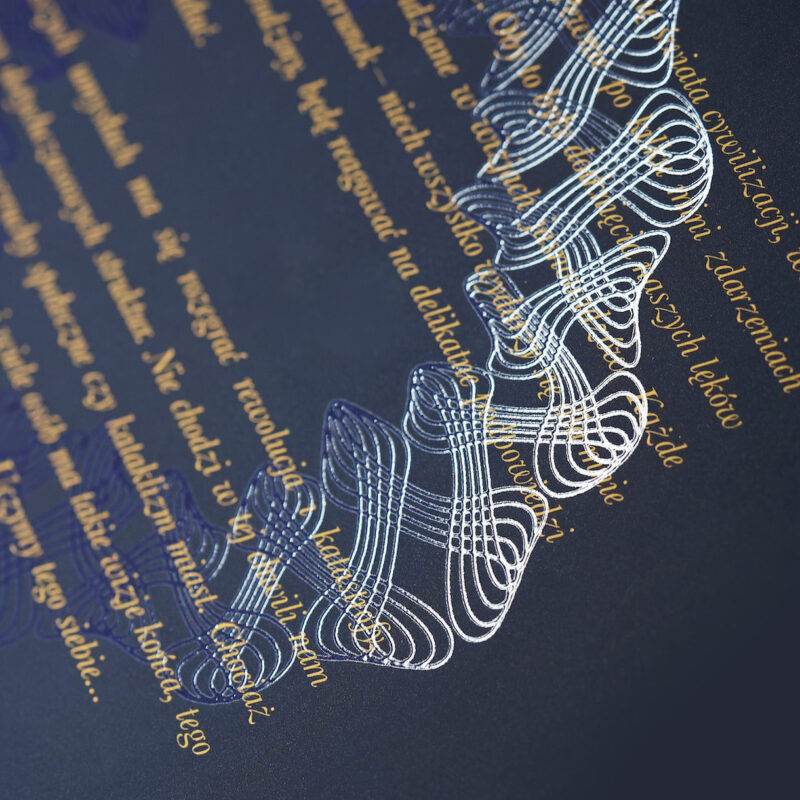

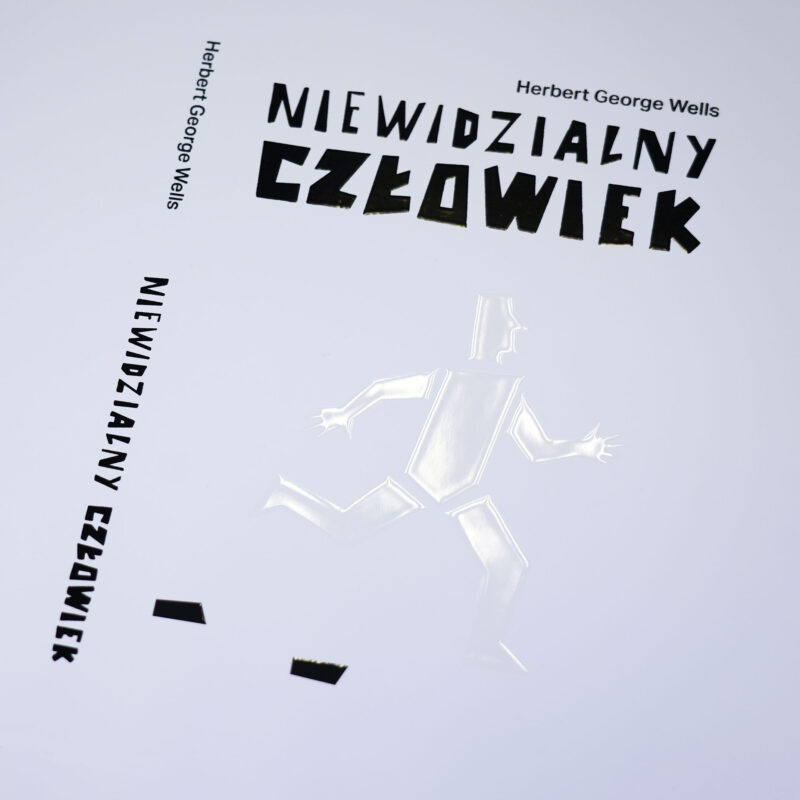

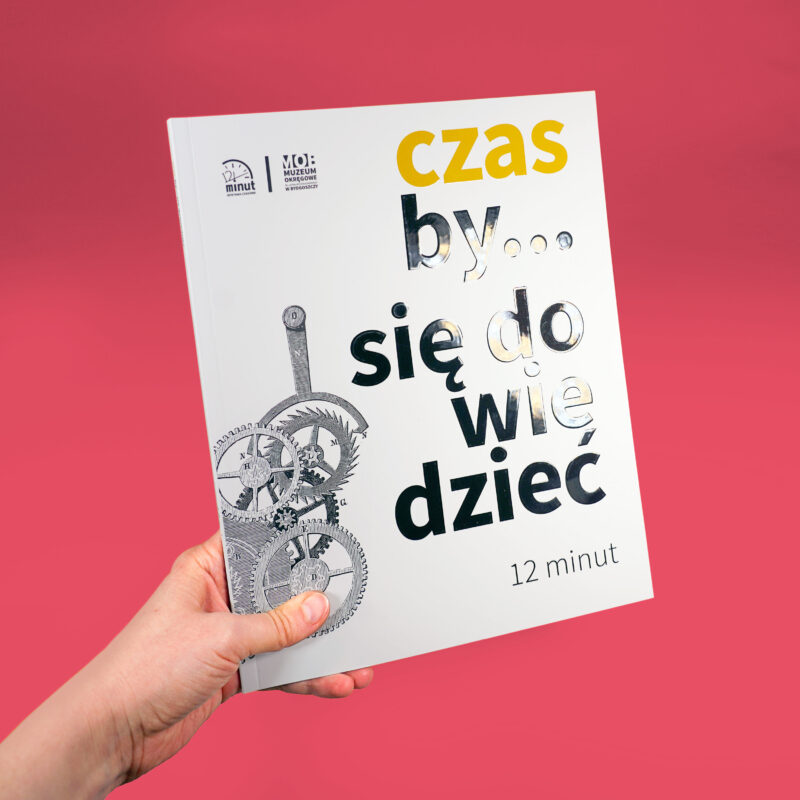

One of the simplest, yet most attractive finishing methods. It involves the application of special UV varnishes in selected areas of the cover to highlight the graphics, the title or the author. When coated, these elements become more visible, catch the eye and draw attention. Varnishes can produce surprising visual effects, especially when they are an integral part of the design, for example when the cover designer uses only varnish to outline the shapes and draw the graphics.

2D Spot Varnish (flat)

Ideal for emphasising critical elements of the cover: the publisher’s logo, the title and illustration details. Most popular in gloss, but also available in a matte version. If used without artwork, it will delicately outline and paint shapes on the cover.

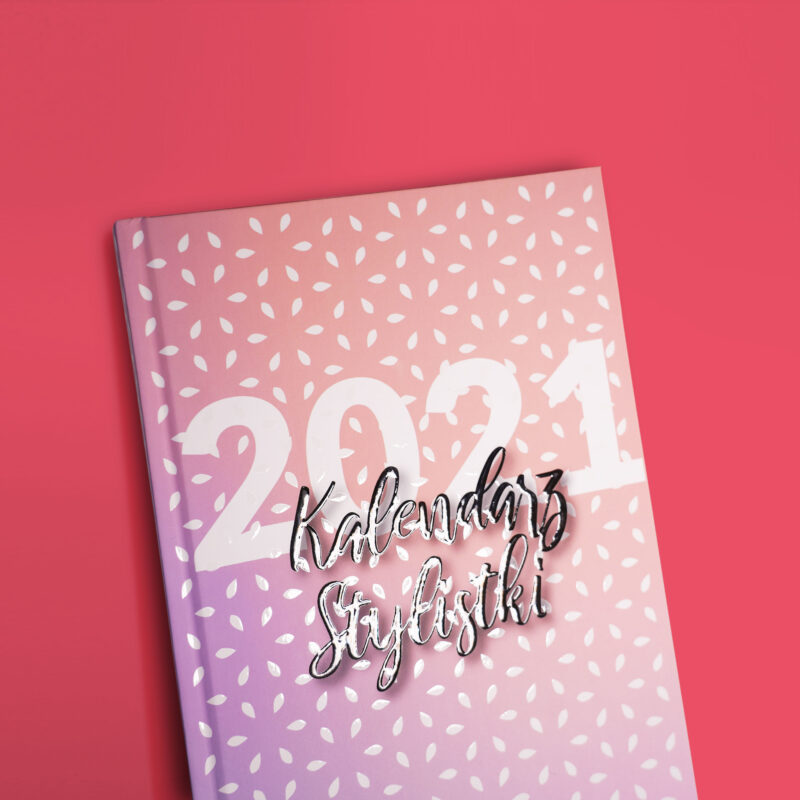

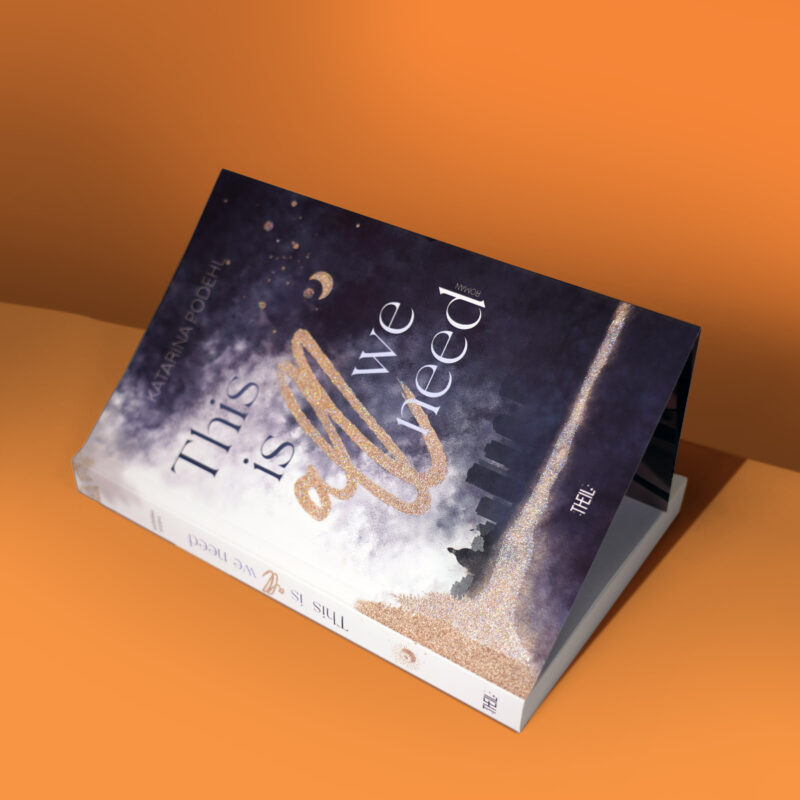

3D Touch – 3D Spot Varnish (raised)

This varnish is used in the digital 3D Touch technology. By using 3D varnish, not only do we achieve spectacular visual effects with a touch of chiaroscuro, but we can also clearly feel the enhanced texture under our fingertips, achieving an extra spatial dimension.

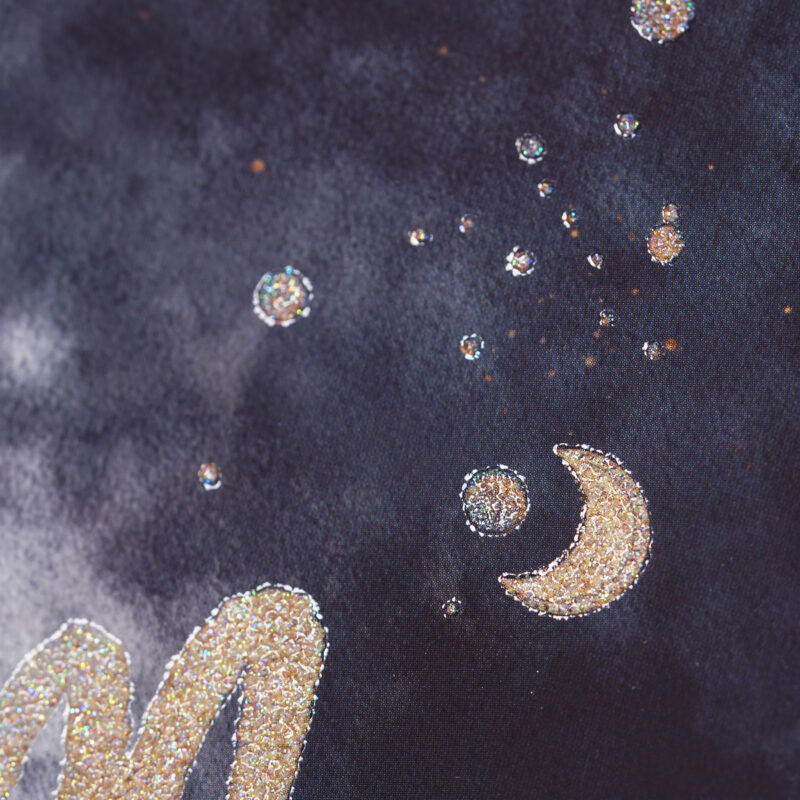

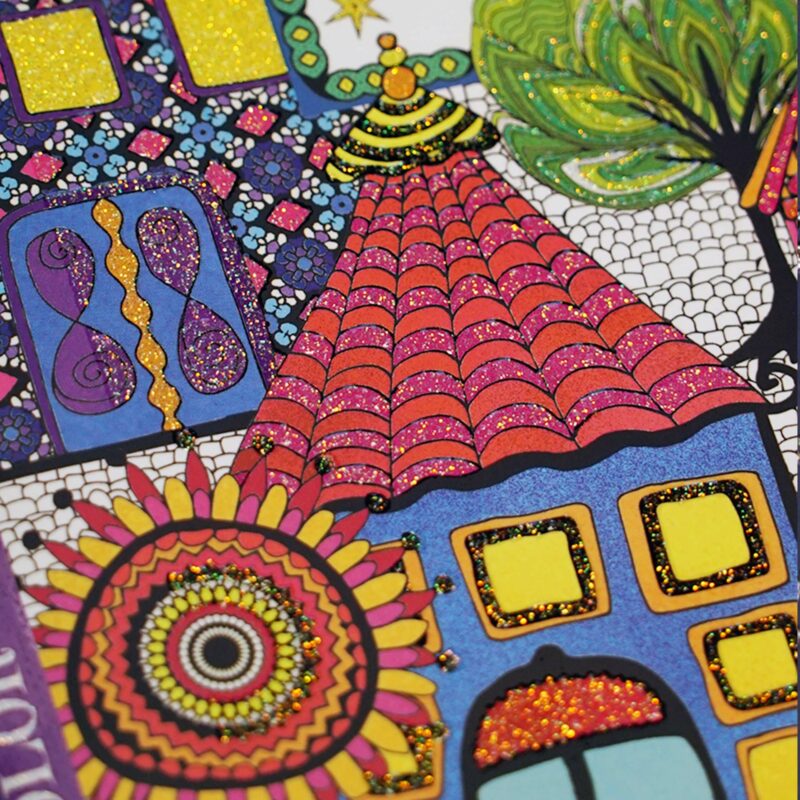

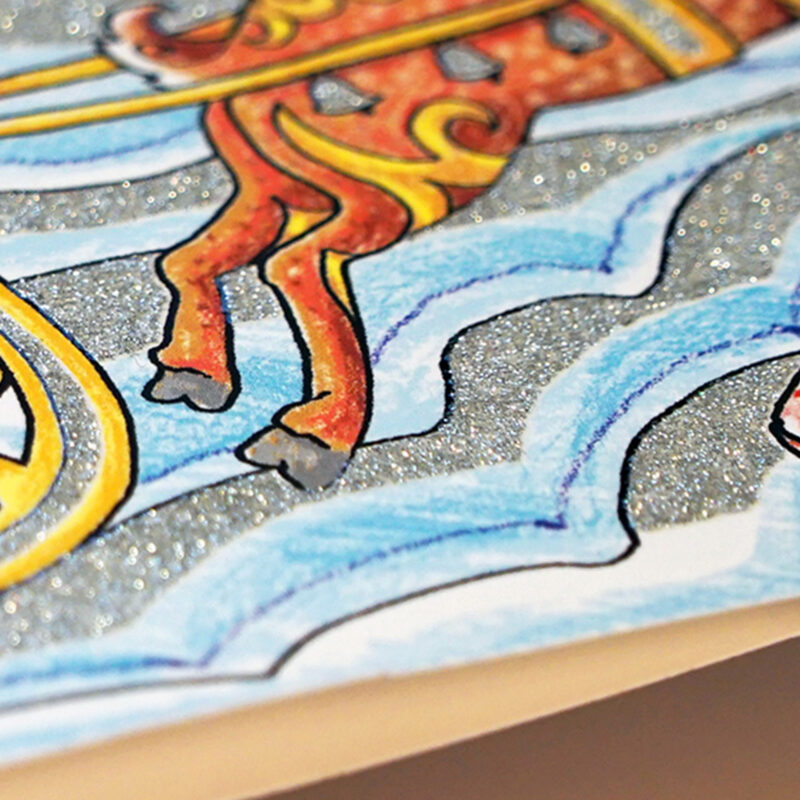

Glitter Varnish

In this varnish glitter particles are suspended producing a spectacular effect. Cover elements painted with glitter varnish sparkle and shine. If applied with care, it is sure to add elegance and sophistication to the design.

See also

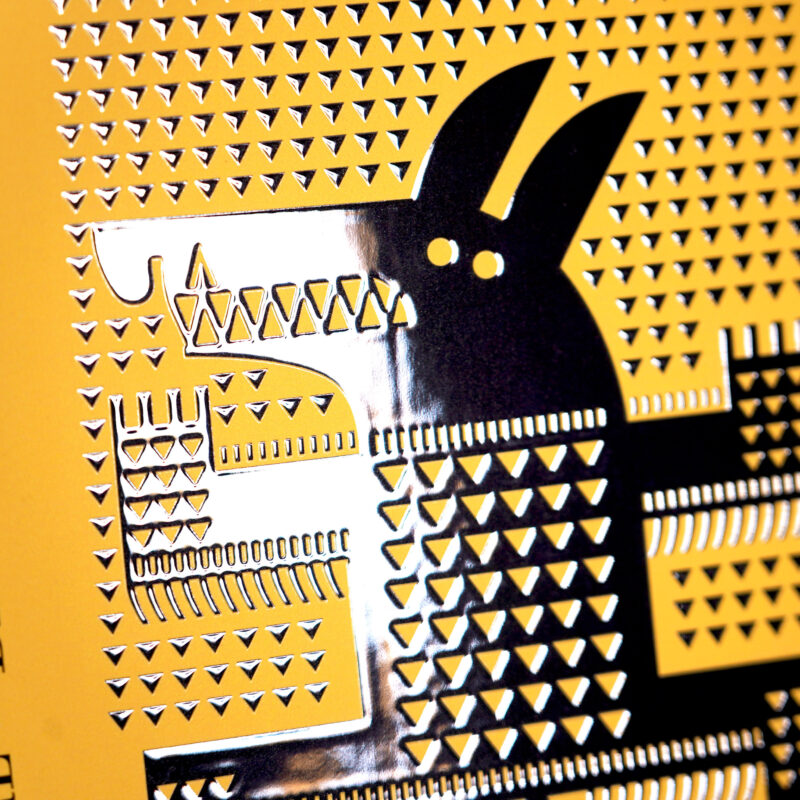

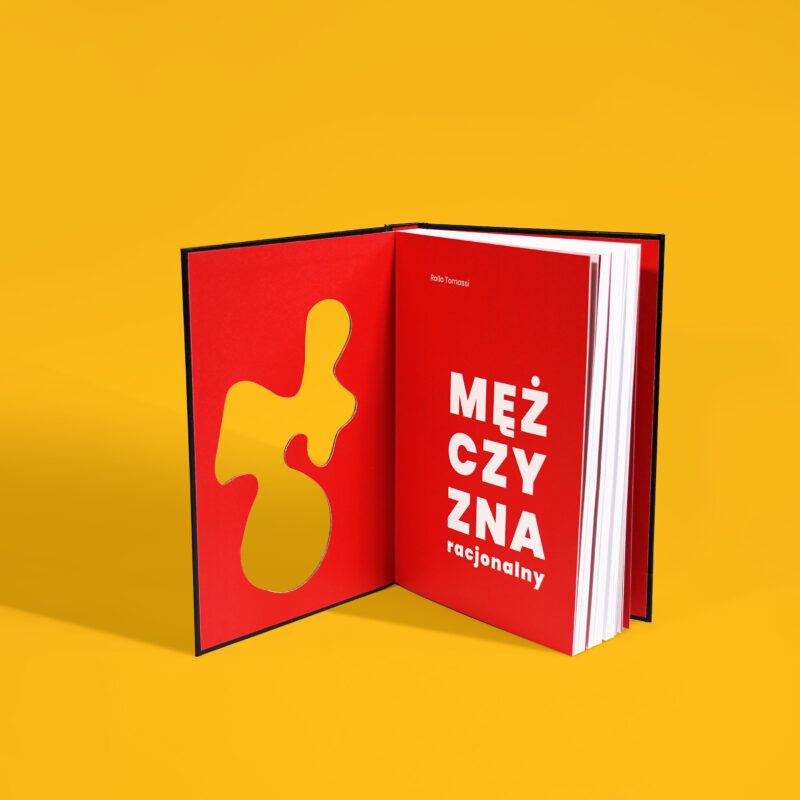

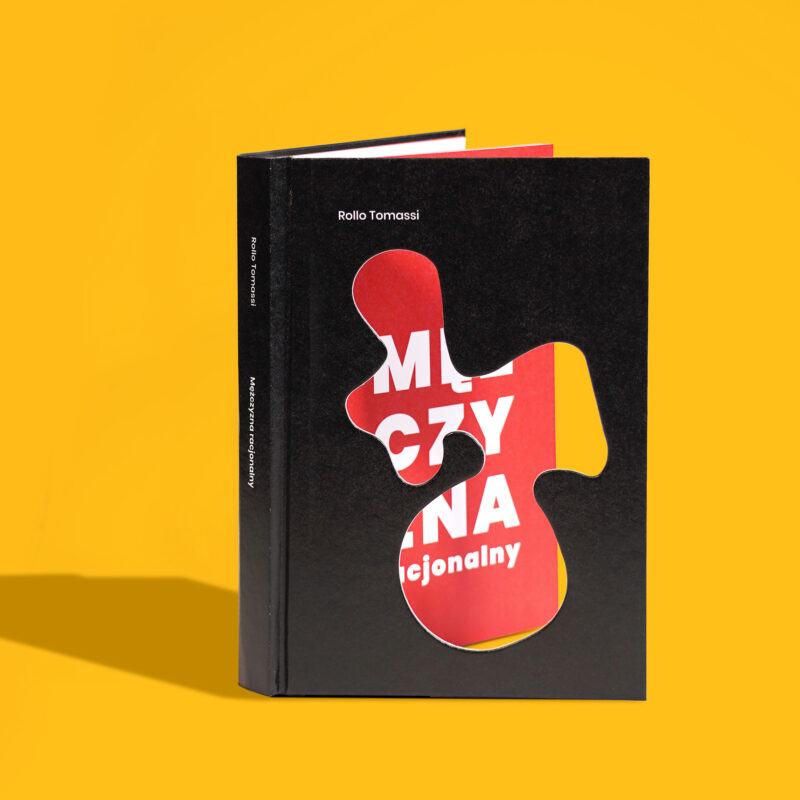

Die-cutting

It involves cutting out any shapes (however fancy they may be) with a special plotter in both soft and hard covers, as well as in dust wrappers and bands. This multiplies the visual experience, especially when the first page of the book block or end paper visible in the hole matches graphically the die-cut shapes. This creates an effect of visual and conceptual consistency.

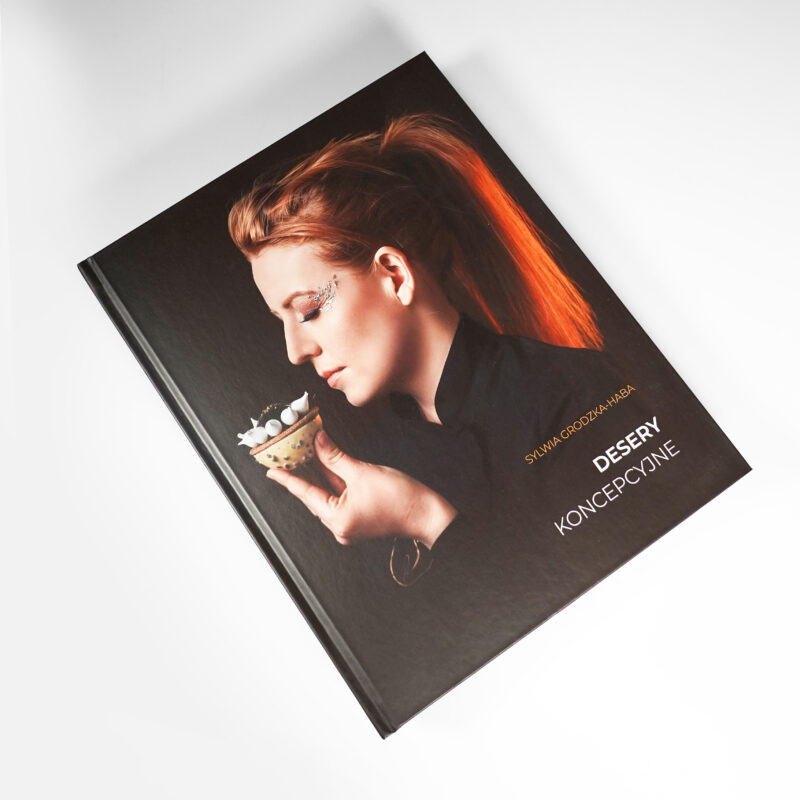

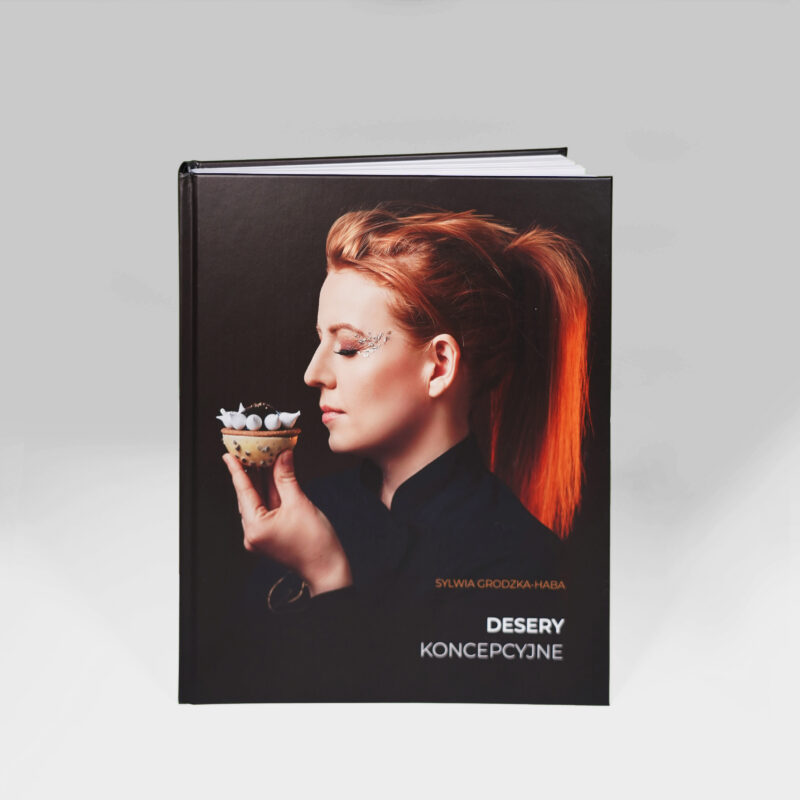

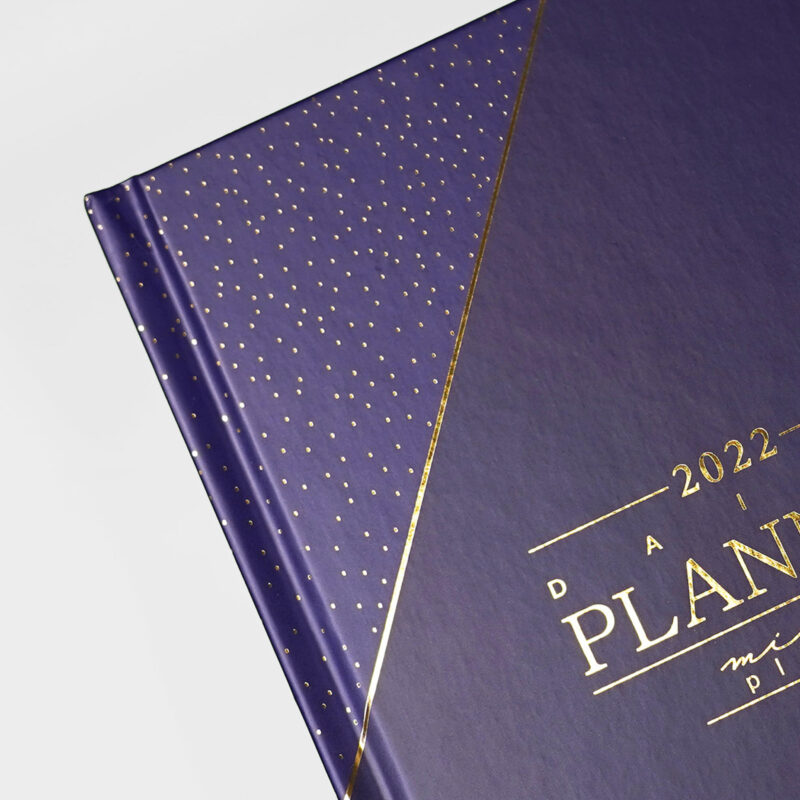

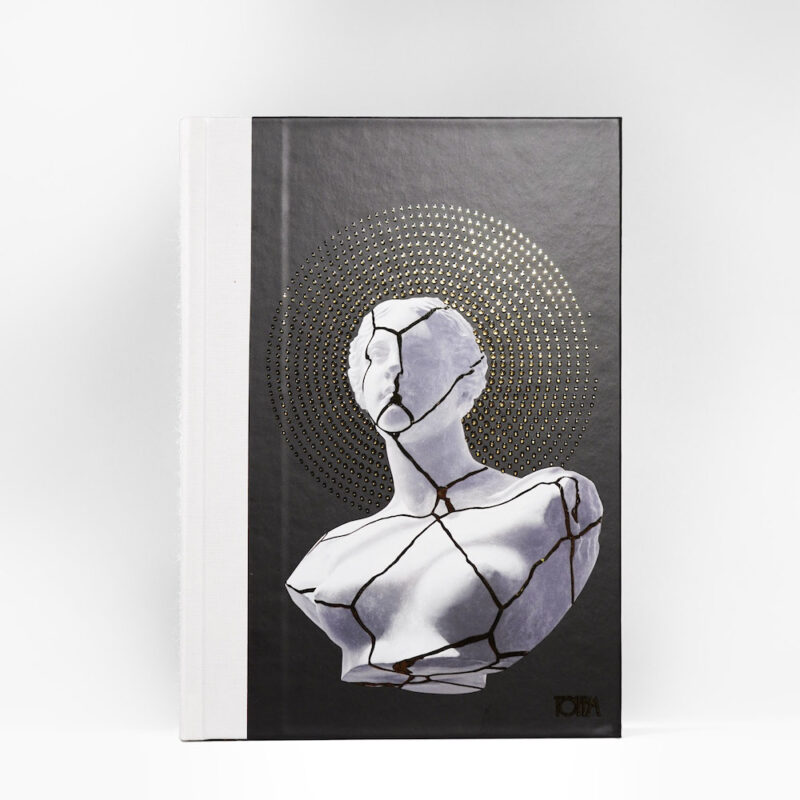

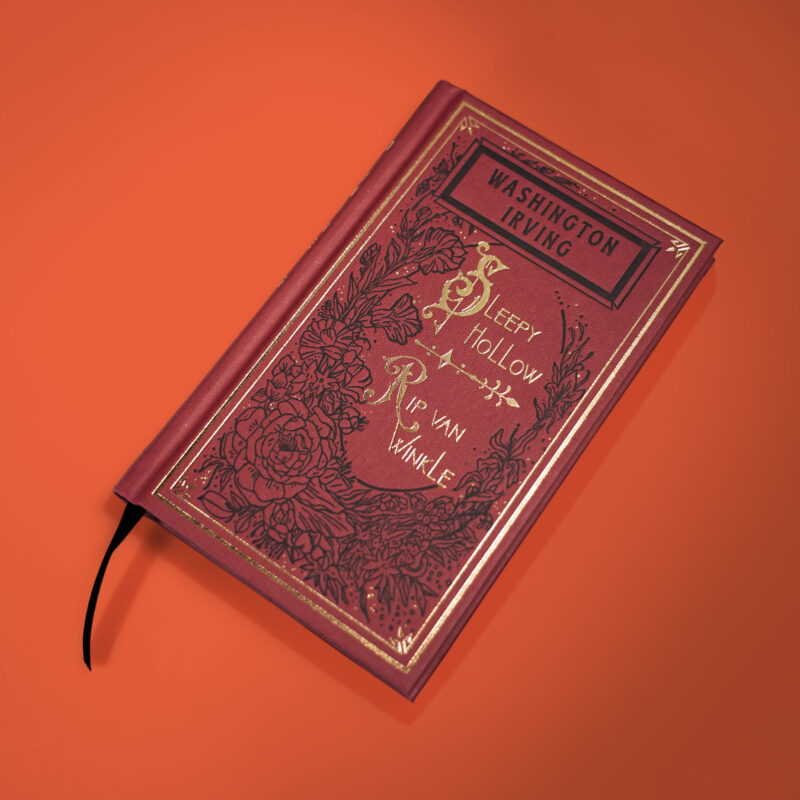

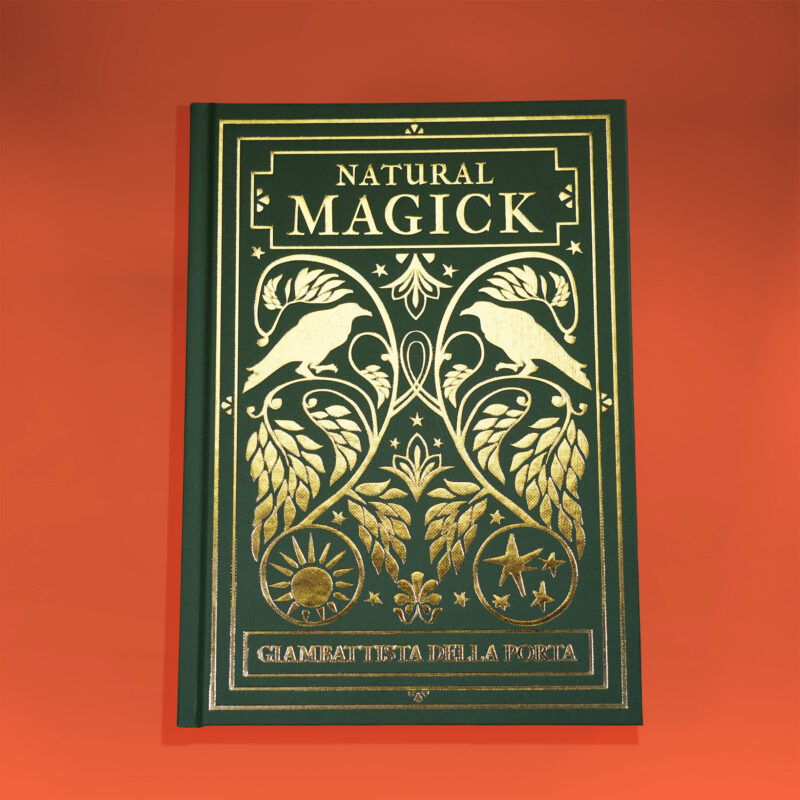

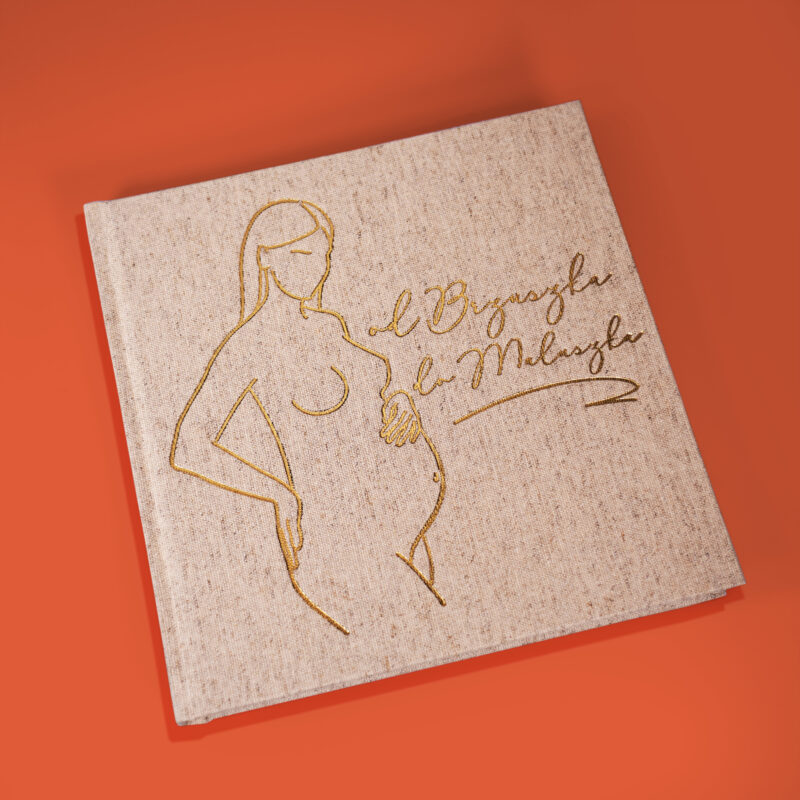

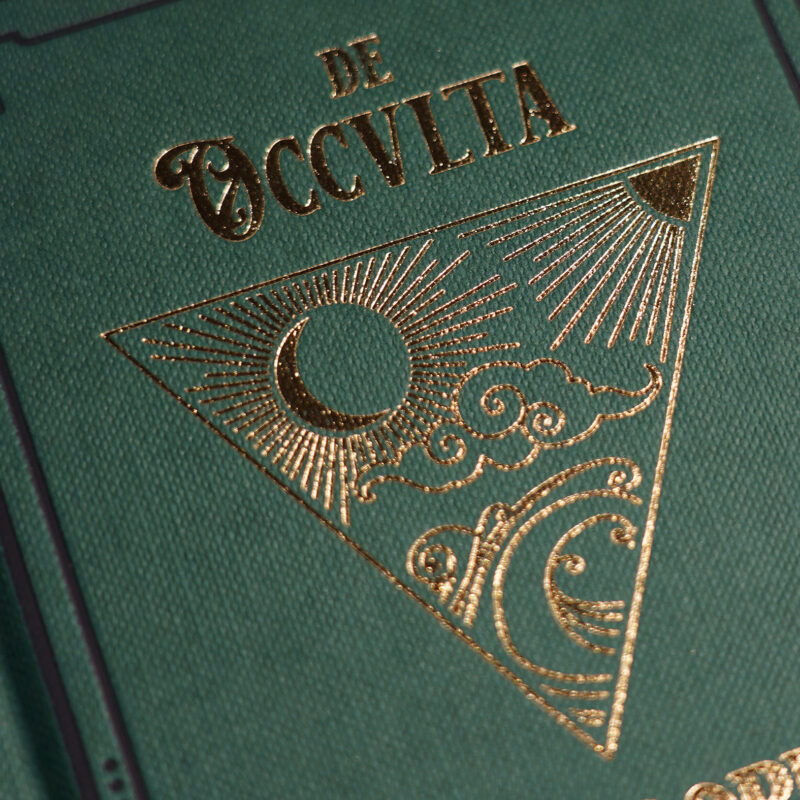

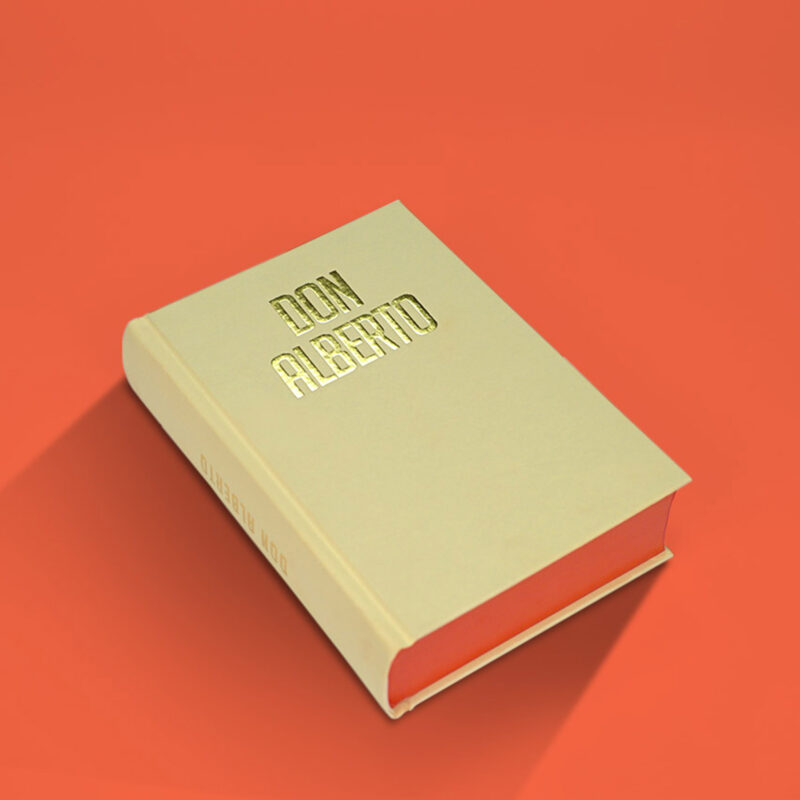

Stamping

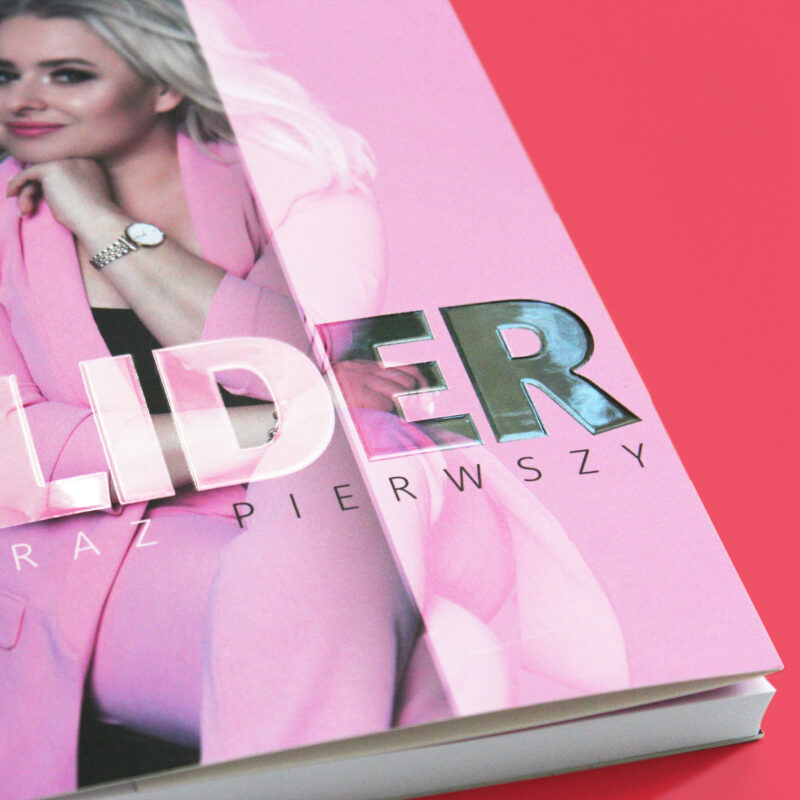

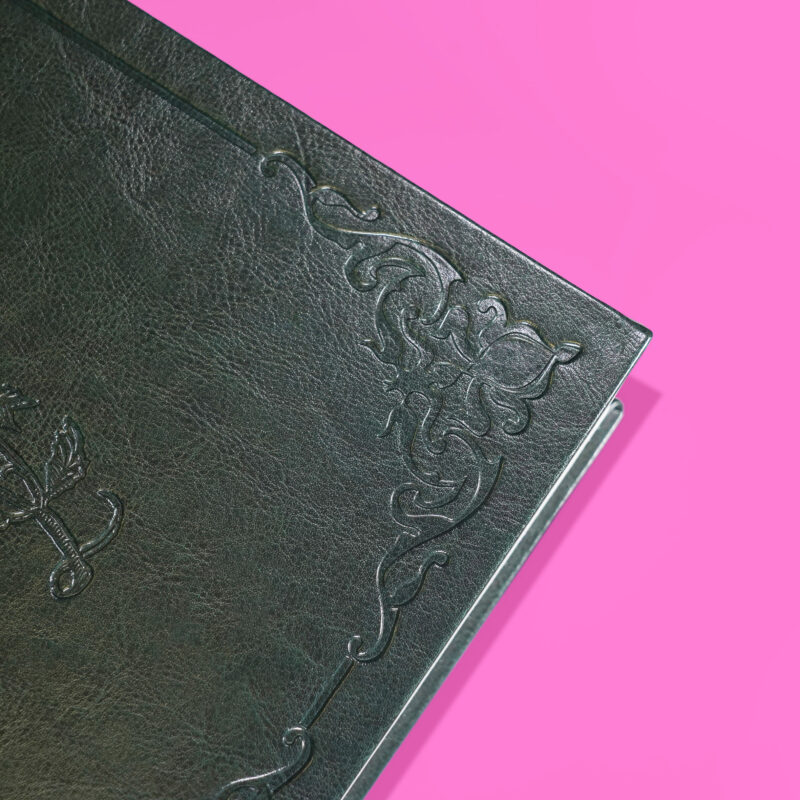

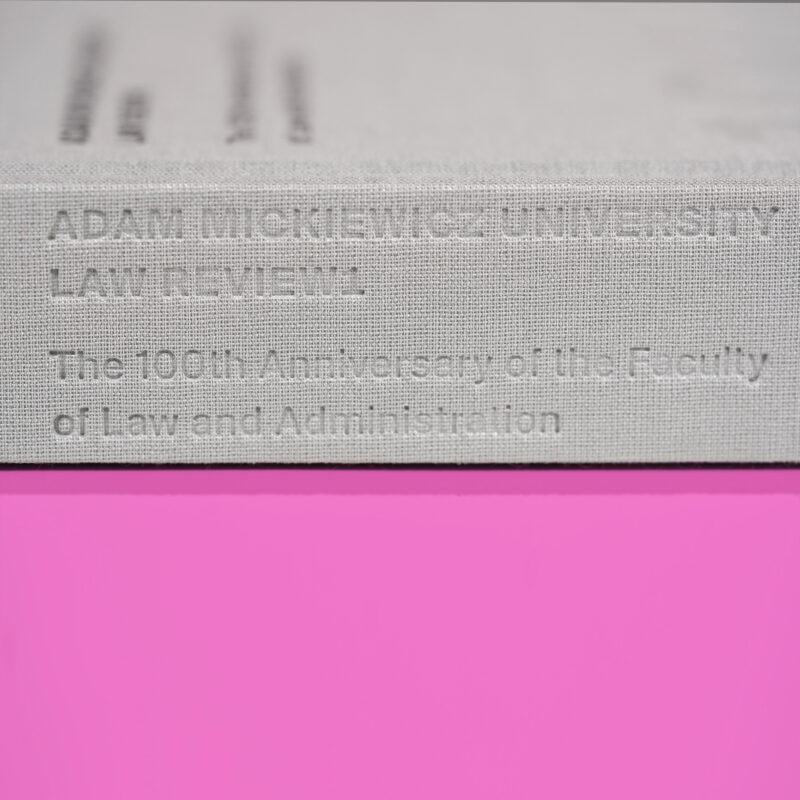

A form of enhancement made by means of a special metal die or counter-die – a kind of ‘stamp’ – which creates the desired shape or pattern in the cover material. When used on a graphic element, it can improve its visibility and emphasize it with a three-dimensional effect. If we press an inscription without prior printing, e.g. in an eco-leather-bound hardcover, a spectacular embossed surface is achieved. We also offer hot stamping with metallized foil.

Debossing

As the die presses against the cover material, it produces a depression. This kind of pressing works best with all types of hard-cover binding: paper, cloth or eco leather.

Embossing

In the case of embossing, the affected area of the cover material is raised, producing clearly visible relief patterns which can be felt with fingers. Embossing is best for all sorts of soft covers.

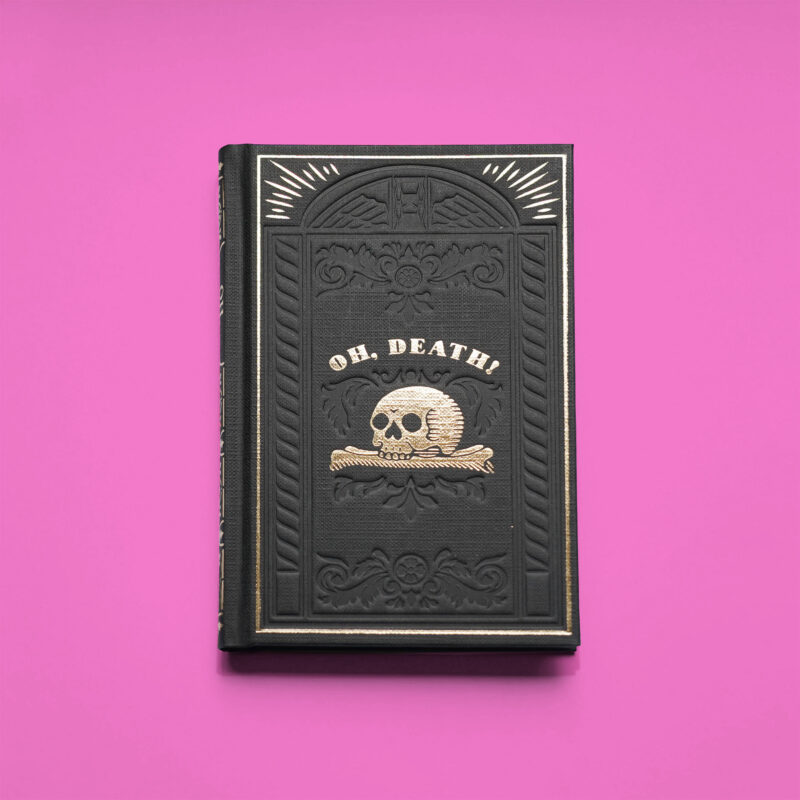

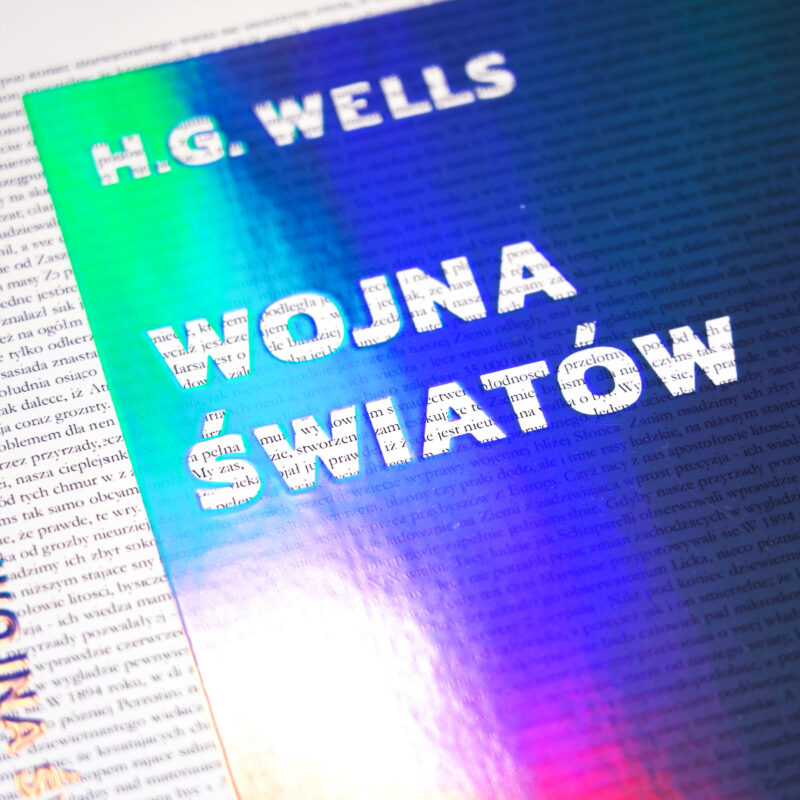

Hot foil stamping

Our printing house offers both the traditional hot foil stamping and the digital 3D Touch technology. We use hot stamping for cases covered with cloth, cork and eco-leather, and the 3D Touch is used with paper cases.

Foil stamping can be applied to each surface of the cover, including the spine and end papers. We offer the following foil colours: golden, silver, red, navy blue and black, as well as holographic films (laser and dot).

Need another colour? Ask and we’ll see what we can do.

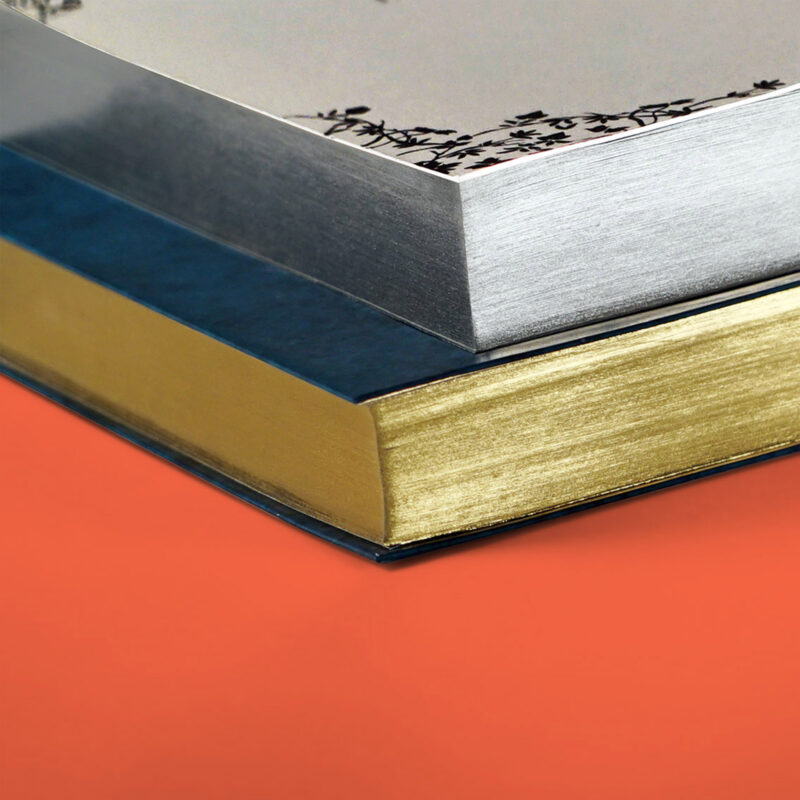

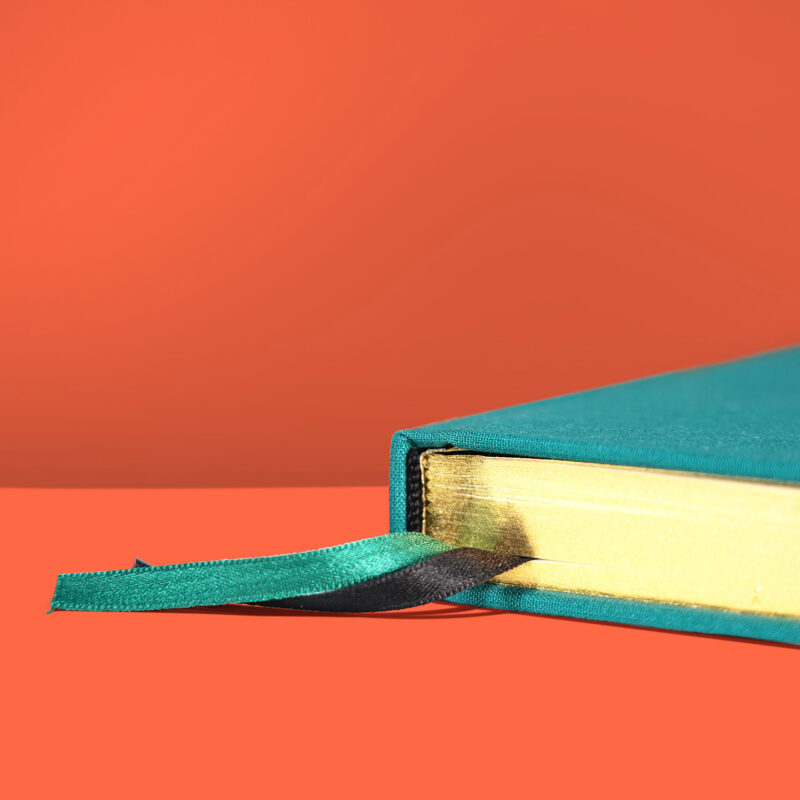

Edge enhancement

A book decorated in this way will not leave anyone indifferent. It is a guarantee that the book will look like no other and will surely stand out on the bookstore shelf.

Book edge staining

The method involves dyeing one or three edges of the book block in any colour. Metallised foils can also be used to achieve the effect of gilding or silvering, reminiscent of old prints or manuscripts. Edge staining also has a protective function, effectively keeping the page edges free of dust. Using metallised foils to enhance the finish works perfectly in reprints, prayer books, albums and publications for collectors.

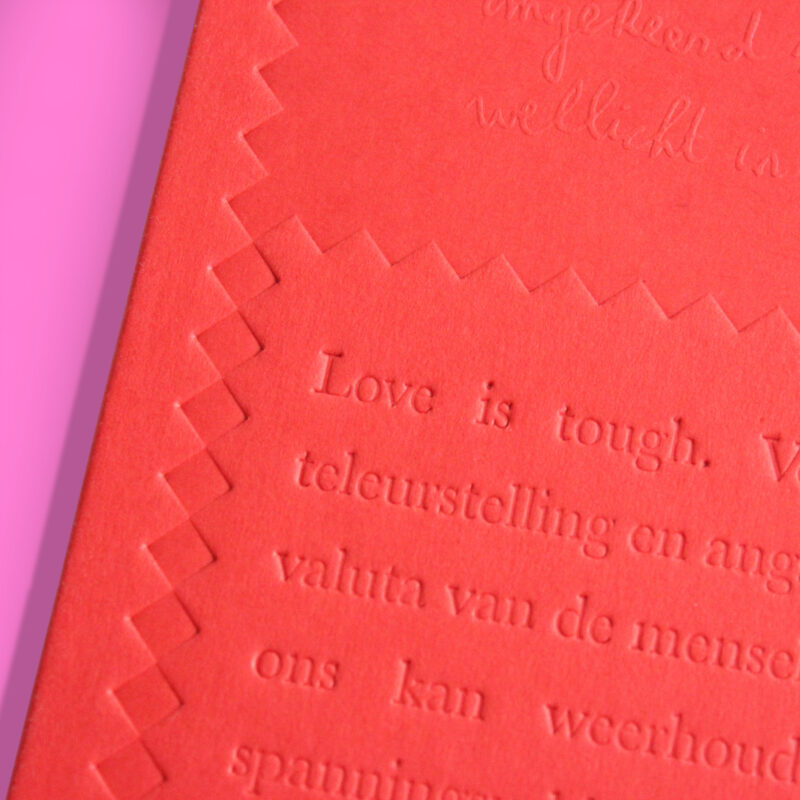

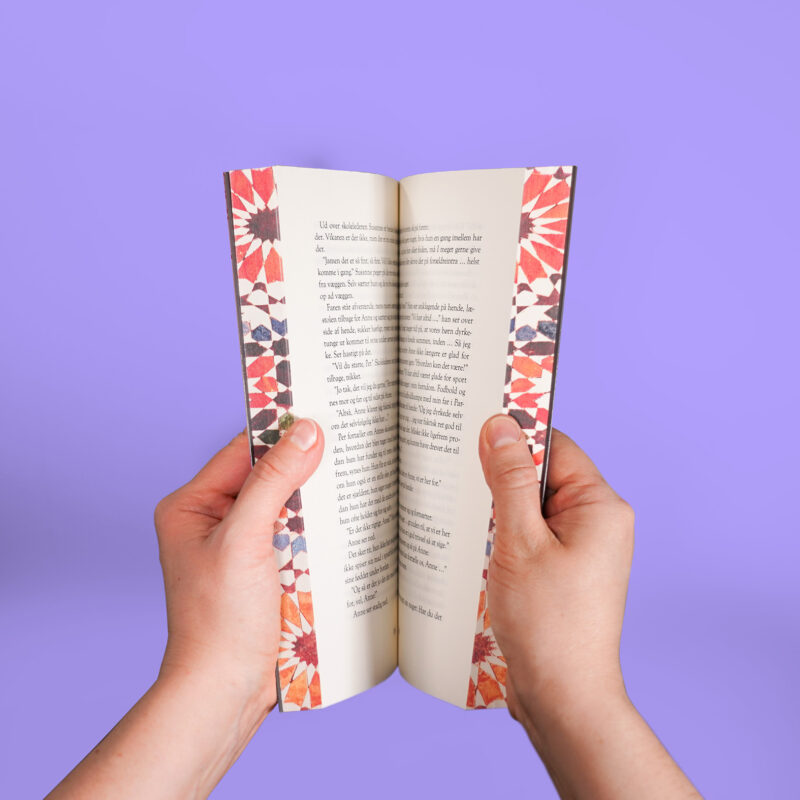

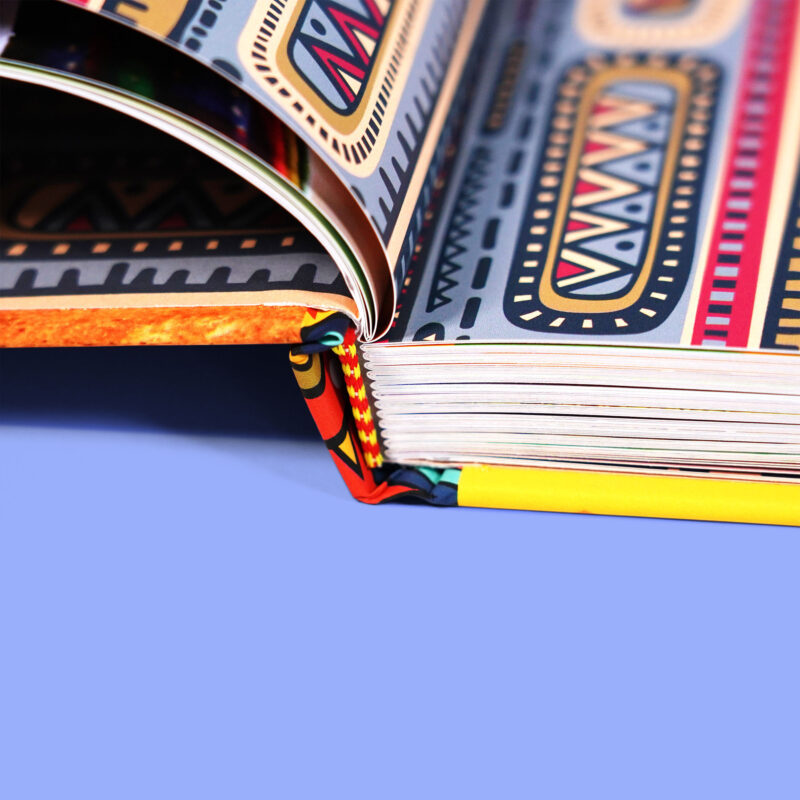

Book edge printing

The edges of your book can be printed with any graphics: illustrations, patterns or ornaments. These can reflect the content of the book or make an additional decorative element to enhance the appearance. Edge printing is great for decorating single books but it seems ideal for multi-volume series of publications. Thanks to the use of a state-of-the-art inkjet printer, at our print shop you can order edge-printing of even a few copies, and have the print customised to your preferences. We also print on book blocks with rounded corners.